From hyper-optimized to shock-resistant

The economic sector is underneath intense strain from a confluence of geopolitical, financial and technological forces. An extended period of hyper-optimized, globe-spanning provide chains is giving technique to extra regional, risk-aware fashions as army tensions, tariff regimes and export-control guidelines reshape the calculus of the place and the way to produce.

Friendshoring, reshoring and nearshoring are now not slogans in coverage papers – they’re reshaping plant footprints and provider rosters. Less complicated elements and completed merchandise are transferring nearer to finish markets to scale back publicity to single-country disruption and to shorten lead occasions. On-demand manufacturing – more and more supported by home additive manufacturing services for spare components – permits operators to chop reliance on distant inventories and to shorten service home windows, which issues each for patrons and for money circulation.

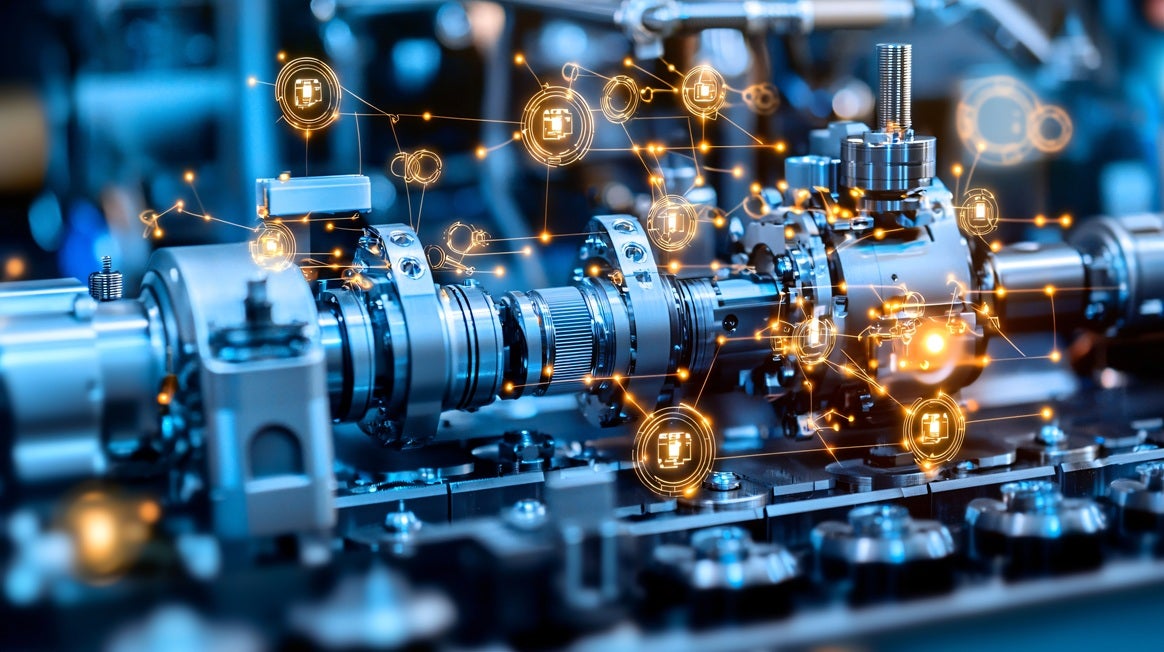

On the identical time, AI-driven demand planning and logistics automation have gotten important for orchestrating multi-source networks with out letting prices run away. IoT sensors and real-time analytics present steady visibility into manufacturing and logistics flows, so managers can spot bottlenecks and deviations early, then intervene earlier than delays cascade throughout the community. That is the sensible face of Trade 4.0 – the “related manufacturing unit” through which machine-level information feeds predictive upkeep routines that schedule interventions mechanically and slash unplanned stoppages.

Digital twins now enable groups to road-test eventualities and prototypes just about, at far decrease value and with far larger velocity than conventional bodily strategies. Robotics and versatile automation can then translate these designs into actuality, permitting services to ramp volumes, swap product variants and rebalance workloads way more rapidly. For buyers and acquirers, the rising hole between crops that embrace these instruments and people that don’t will more and more be seen in margins, reliability metrics and asset productiveness.

For resolution makers at industrial companies the strategic objectives are clear sufficient. First, cut back disruption threat and lift restoration capability when shocks hit. Second, harness the advantages of recent expertise whereas protecting cyber, operational and regulatory dangers underneath management. The problem lies in execution. The structural shifts reshaping industrials are uneven throughout areas and subsectors, which implies there will be no one-size-fits-all playbook.

Regional realignments reshape the commercial map

The geography of business manufacturing is fragmenting and re-concentrating on the identical time. Understanding this patchwork is vital for boards, corporate-development groups and dealmakers seeking to place portfolios for the subsequent decade.

In the USA, coverage is actively pulling strategic manufacturing house. Semiconductor fabs and EV crops are rising on the again of federal incentives, whereas commerce measures on metals and different inputs are reshaping value curves and pushing firms to reassess long-standing sourcing methods. Many producers now weigh the premium of a US footprint in opposition to the tariff and regulatory publicity related to imports. The result is a deeper home ecosystem – and a tighter linkage between plant location, expertise depth and privileged entry to the US market.

Europe is following a distinct path, taking part in to its strengths in high-precision, automation-rich manufacturing and in green-technology purposes the place engineering excellence justifies premium pricing. Coverage once more isn’t a sideshow however a part of the technique. The EU’s Carbon Border Adjustment Mechanism will levy duties on high-carbon imports, successfully tilting the taking part in discipline towards cleaner native output. Scandinavian steelmakers advancing hydrogen-based “inexperienced metal” supply a glimpse of the place aggressive benefit and valuation uplifts are prone to accrue as carbon constraints tighten.

Throughout Asia, structural shifts are having a bifurcated impact. China is pushing arduous up the worth chain in robotics, aerospace and clean-energy applied sciences, constructing formidable capability in a number of of the sectors buyers care about most. On the identical time, rising labor prices, rising regulatory scrutiny and the persistent menace of tariffs or export controls are accelerating diversification away from China. Its beforehand unchallenged centrality to world manufacturing can now not be taken with no consideration.

Consequently, different Asian economies are capturing share. Vietnam continues to construct its place in electronics and attire as OEMs diversify their footprints. India is increasing in chemical compounds, electronics meeting and broader manufacturing as reforms and infrastructure funding make it a extra reasonable different for scale manufacturing. For industrial strategists and M&A groups, this creates new regional clusters and potential acquisition targets, but additionally new supply-chain dependencies to handle.

An analogous sample is rising past Asia. Mexico is a transparent beneficiary of US nearshoring, with exports of automotive components and electronics climbing as producers rebalance manufacturing nearer to North American prospects. Elements of Africa are starting to draw funding in clothes, automotive elements and adjoining meeting as companies search to scale back single-country focus and faucet youthful labor swimming pools. China’s Belt and Highway funding is massively extending manufacturing and logistics capability throughout the continent, from ports to industrial zones, and can redraw the commercial map nonetheless additional over the approaching decade.

On this setting, asset location, expertise content material and coverage publicity are more and more intertwined. For buyers, valuations will rely not simply on what an organization makes however the place it operates and the way adaptable its footprint is to future shocks.

A strategic playbook for operators and dealmakers

A semiconductor startup within the US, a garments producer in Poland and an Africa-based logistics enterprise can not sensibly undertake similar methods in response to those shifts. But the underlying pressures – fragmented commerce, local weather coverage, technological acceleration and supply-chain threat – are pervasive. The query for boards and deal groups is the way to reply in ways in which construct sturdy benefit reasonably than including complexity.

Three strategic changes stand out.

First, product design wants regional flexibility. Payments of supplies must be structured in order that suppliers will be swapped by geography whereas nonetheless satisfying native content material guidelines, tariff thresholds and buyer specs. Which means standardizing the place doable, modularizing the place mandatory and constructing clear choices into designs from the outset. For acquisitive teams, due diligence more and more has to ask whether or not a goal’s product structure will constrain footprint flexibility or allow it.

Second, procurement and planning must be rewired for steady situation testing. Digital twins of crops, distribution facilities and end-to-end networks enable managers to mannequin completely different commerce, energy-price and transport assumptions earlier than committing capital or rerouting flows. This functionality is now not a luxurious for world-scale teams alone. As instruments turn out to be extra accessible, even midsized producers can simulate the associated fee and repair impression of other sourcing configurations or transport modes, then revisit these selections as circumstances shift. For personal-equity sponsors, the presence or absence of such capabilities will more and more form each thesis improvement and value-creation plans.

Third, safety structure should prolong past the enterprise boundary to cowl suppliers and logistics companions. As ecosystems turn out to be extra related and information flows multiply, vulnerabilities at a small provider or freight middleman can current outsized threat. Cybersecurity, data-access controls and operational-technology safety subsequently must be designed for the community, not simply the person plant. Traders and lenders are already starting to ask harder questions on cyber resilience; industrial teams that may display strong, ecosystem-wide safeguards might be higher positioned to win contracts and defend valuations.

Corporations that mix regional manufacturing with data-rich operations are finest positioned to ship steadier service and quicker response whilst commerce friction and coverage shifts persist. Robotics, superior analytics and simulation capability are already making their manner onto shopfloors. These instruments are the levers that may maintain unit prices in test when manufacturing spreads throughout areas and when provide chains have to flex at quick discover.

Positioning for the subsequent industrial cycle

The course of journey is evident. Excessive-technology factories, diversified footprints and sharper threat administration have gotten the defining traits of business winners. No matter their fundamental line of enterprise and wherever they’re primarily based, the businesses that thrive in a restructured industrial panorama might be people who transfer early, that deal with resilience and suppleness as core design rules reasonably than afterthoughts, and that align capital allocation with this new actuality.

For boards, corporate-development leaders and M&A dealmakers, which means reassessing portfolios by a structural lens. Which property are tied to fragile provide chains or carbon-exposed processes. Which geographies are prone to achieve or lose coverage help. The place does the expertise stack – from robotics to information infrastructure – lag friends, and what would it not take to shut the hole. These questions will form not solely operational methods but additionally the sample of dealmaking in industrials over the approaching decade.

Uncover additional insights

To study extra, obtain our report – The Way forward for Industrials: Insights for Traders & Dealmakers – printed in affiliation with Sterling Expertise – the supplier of premium digital information room options for safe sharing of content material and collaboration for the funding banking, non-public fairness, company improvement, capital markets, and authorized communities engaged in industrials M&A dealmaking and capital elevating.