Intel has unveiled technical specs for its upcoming consumer processor, the Core Extremely collection 3, identified internally as Panther Lake.

In keeping with Intel, Panther Lake is the primary processor fabricated utilizing the corporate’s 18A course of node, a 2nm class know-how developed and manufactured within the US.

Preliminary shipments of Panther Lake are scheduled for later in 2025, with wider industrial availability deliberate for January 2026.

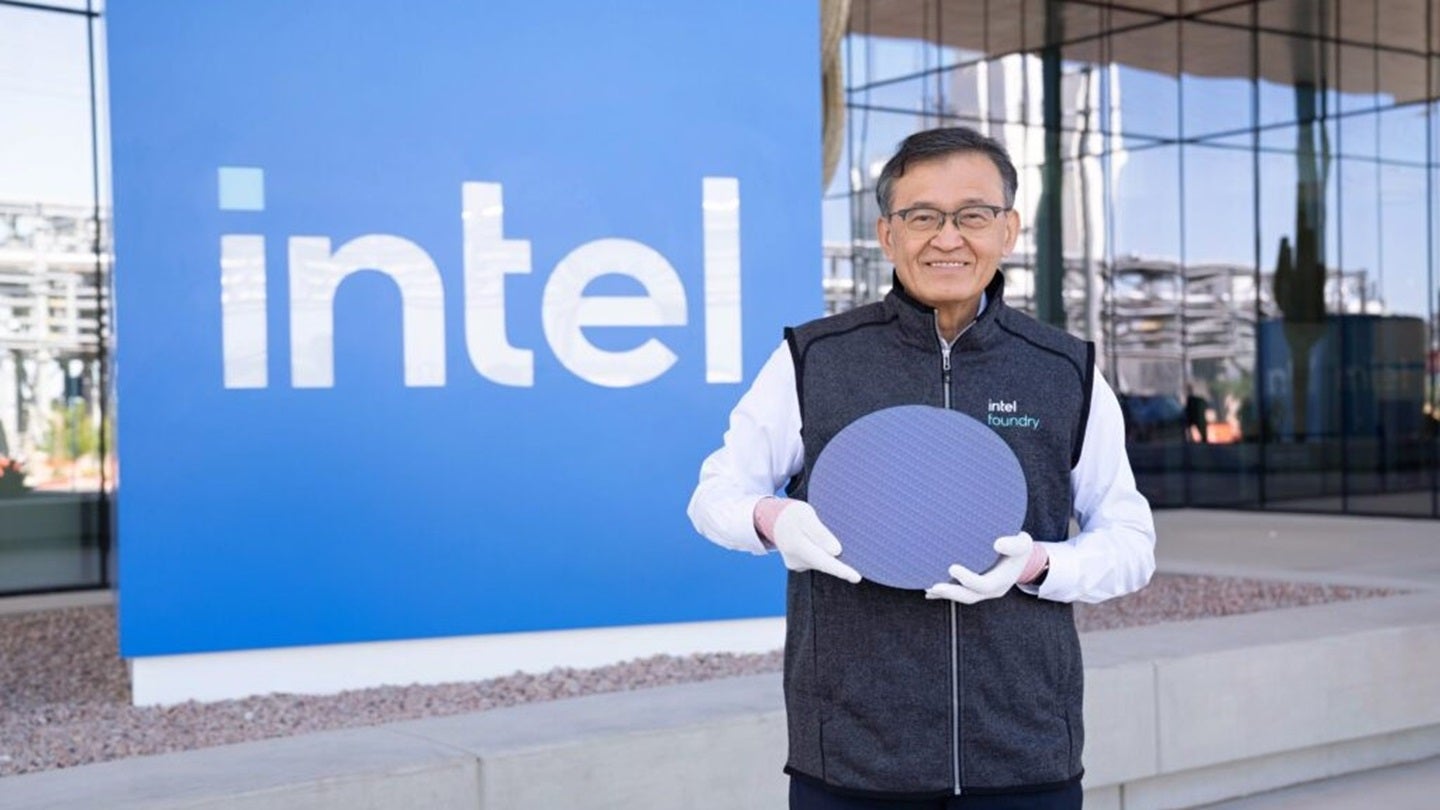

The processor will likely be produced at Fab 52 in Chandler, Arizona.

Panther Lake incorporates a multi-chiplet system-on-chip structure and is constructed to serve a variety of functions, together with AI PCs, gaming methods, and edge deployments.

It options as much as 16 mixed efficiency and environment friendly cores, and an built-in Intel Arc graphics processing unit (GPU) with as much as 12 Xe cores.

In keeping with Intel’s inside measurements, Panther Lake delivers over 50% enchancment in CPU and graphics efficiency in comparison with earlier generations and helps as much as 180 trillions of operations per second (TOPS) for AI workloads.

The platform additionally extends to edge computing, akin to robotics, with Intel offering a devoted robotics AI software program suite and reference board.

Intel CEO Lip-Bu Tan stated: “We’re coming into an thrilling new period of computing, made potential by nice leaps ahead in semiconductor know-how that may form the long run for many years to return.

“Our next-gen compute platforms, mixed with our modern course of know-how, manufacturing and superior packaging capabilities, are catalysts for innovation throughout our enterprise as we construct a brand new Intel.”

Within the information centre section, Intel previewed Clearwater Forest, the corporate’s subsequent era Xeon server processor, branded as Xeon 6+.

Additionally based mostly on the Intel 18A course of node, Xeon 6+ is about for launch within the first half of 2026. It gives as much as 288 environment friendly cores and is claimed to ship a 17% enhance in directions per cycle versus its predecessor.

Clearwater Forest targets hyperscale information centres, cloud suppliers, and telecommunications environments requiring excessive workload density and effectivity.

The Intel 18A course of node introduces RibbonFET transistors and PowerVia bottom energy supply. These additions permit for larger chip density and improved power effectivity in comparison with earlier Intel nodes.

The manufacturing movement leverages Foveros packaging know-how, enabling stacking and integration of a number of chiplets in a single package deal.

Fab 52 represents an growth of Intel’s US manufacturing infrastructure, becoming a member of analysis and growth (R&D) services in Oregon and packaging operations in New Mexico.

The corporate’s funding in Arizona kinds a part of a $100bn plan to broaden home semiconductor manufacturing capability.

In September 2025, Nvidia plans to speculate $5bn in Intel to co-develop customized information centres and PC merchandise. This follows the US authorities’s current $8.9bn funding in Intel to reinforce home semiconductor manufacturing.