In the present day’s automobiles are computer systems on wheels. The marketplace for linked automobiles is estimated at round US$38.5 billion in worth as we speak and is forecast to succeed in US$52.9 billion by 2030. {Hardware} corresponding to sensors and connectivity modules are already price over US$15 billion a 12 months; service revenues are even increased.

However there are challenges on the horizon. Demand for electrical and software-defined automobiles is ready to soar from 13.5 million models in 2023 to greater than 80 million by 2035, a compound annual development price near 16%.[1] But electrical drivetrains, whereas requiring fewer mechanical elements, introduce new provide dangers round batteries and semiconductors. Battery supplies corresponding to lithium, cobalt and nickel are in tight provide, and up to date chip shortages have uncovered fragilities in world sourcing.

Moreover, long-standing points round having to remodel bodily prototypes, re-tool strains or await elements impacts margins. With a single misplaced hour in automotive manufacturing costing anyplace from US$36,000 to greater than US$2 million, designers and producers can’t afford the results of such unpredictability.

Thankfully, as fashionable automobiles evolve, so too are the instruments used to design and engineer them. Prolonged Actuality (XR) – an umbrella time period for augmented, combined and digital actuality – are gaining floor. In transportation and automotive alone, XR revenues are projected to rise from roughly US$290 million in 2024 to US$2.9 billion by 2030.

Intricate design wants stay paramount and provide chain challenges are piling on uncertainty. Towards this backdrop, XR gives a option to carry automotive digital twins – an in depth, continuously up to date mannequin of the automobile and its manufacturing context – right into a shared, immersive atmosphere. Augmented actuality retains engineers in the true world with digital overlays. Digital actuality enhances this by inserting them inside a full-scale digital automobile or manufacturing unit with hand-held controllers and monitoring. Quite than substitute current instruments, these environments prolong them, offering a richer view of the identical knowledge.

Main modifications within the auto design world

For many years, design evaluations have regarded a lot the identical: engineers huddle round screens, rotate knowledge heavy 3D fashions with a mouse and talk about key design choices. A lot of the true checking solely occurs in a while bodily prototypes – which might simply be despatched again to the drafting board.

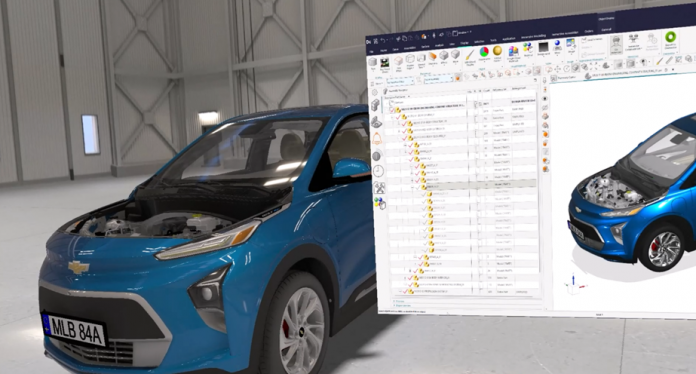

New immersive instruments are shaking issues up. Many design methods are actually constructing digital actuality immediately into the core computer-aided design atmosphere. By way of Immersive Engineering, a Siemens answer, engineers can placed on the Sony headset tuned for detailed engineering work and see a full-sized automobile, with hand controllers used for pointing, navigation and interplay.

The work itself doesn’t change in precept; a specialist chargeable for checking that automobiles might be assembled and serviced, nonetheless wants to examine crowded areas corresponding to wheel arches, engine bays and undertrays. However now, in an immersive session, that individual can place themselves contained in the digital wheel arch, entry the Meeting Viewer, spotlight particular person elements after which stroll as much as bigger sub-assemblies. Complete methods such because the wheel and brake might be hidden in a single transfer, clearing the view for extra detailed investigation.

Alongside this bodily sense of presence sits a set of analytical instruments that might be not possible in an actual workshop. Part planes might be positioned within the immersive atmosphere to reveal hidden elements and verify packaging in tight areas. Measurement capabilities make it straightforward to seize clearances, both with approximate picks or actual references, with out looking by views and menus. Mark-up instruments let the reviewer circle areas of concern and add notes which can be saved as snapshots, which might be revisited in later classes or shared with colleagues.

Most significantly, this all takes place in real-time. Within the immersive atmosphere, customers can place a Digital Monitor to make design modifications. Moreover, an engineer can disguise elements or alter the configuration in the usual interface and see the modifications seem immediately on the full-scale mannequin round them. There is no such thing as a export step, no secondary dataset to take care of and no delay between altering the design and understanding its penalties.

Collectively, these capabilities make XR a productiveness powerhouse; engineers acquire a clearer grasp of how complicated assemblies match collectively, slashing the prospect of late surprises on bodily prototypes and serving to groups make higher choices earlier within the course of. And the advantages are beginning to crystalize. Siemens’ buyer references level to productiveness beneficial properties in design duties of round 30% when groups transfer to built-in immersive workflows, along with a marked fall within the variety of bodily prototypes required.

Turning to the consultants

A current GlobalData survey discovered that almost 70% of senior decision-makers count on augmented actuality to alter on a regular basis enterprise over the approaching decade. Regardless of the productiveness advantages on provide for car companies, and the widespread perception that change is coming, limitations abound: restricted time to plan, a scarcity of in-house experience and issue linking pilot tasks to clear business outcomes.

That’s the place specialist companions are available in. An immersive session inside immersive engineering offers three inter-connected choices; Immersive Explorer for fast design evaluations, Immersive Designer for making and evaluating modifications in VR, and Immersive Collaborator for digital assembly rooms that join employees and suppliers throughout continents. The crew at Siemens Immersive are readily available to assist automobile designers deploy Designcenter NX as we speak.

For automotive resolution makers wrestling with electrification, provide disruptions and abilities shortages, Immersive Engineering is a sensible plan of assault. It compresses resolution time, cuts the price of errors and helps new employees construct confidence extra rapidly in practical, low-risk environments. As XR revenues climb, design centres that stand on the innovative of those developments will probably be poised to steer the trade into the longer term. Are you able to afford to overlook out? Fill in your particulars now to be taught extra.

[1] ABi Analysis report, “Immersive Automotive Engineering”