From the variety of groups, to the distances between them, and the number of disciplines that should agree on design selections, the complexities concerned in trendy automotive design are big. At this time’s automobiles pull collectively mechanical packaging, electronics, software program, security necessities, manufacturability and repair entry. Every space brings its personal specialists, suppliers and requirements.

These complexities imply conventional overview processes wrestle below that weight. Probably the most consequential discussions proceed often happen round screens – a design group can struggled to get a real sense of scale for a brand new product. Unidentified design flaws could cause main points additional on in workflows; groups might uncover a bodily prototype has a clumsy fastener, sub-optimal association or an ignored upkeep operation.

Moreover, new autonomous and electrical automobiles are overhauling what vehicles appear to be on the within: batteries, energy electronics and software-defined options add new interfaces, but additionally new factors of failure. Completely different regional rules and the requirements they have to meet piles on complexity.

What’s lacking is a shared sense of presence round these advanced digital twins. The flexibility for a world design group to take a look at the identical product iteration, at true scale, in real-time, and to have the ability to seize key design selections is important.

The reply: Built-in design processes

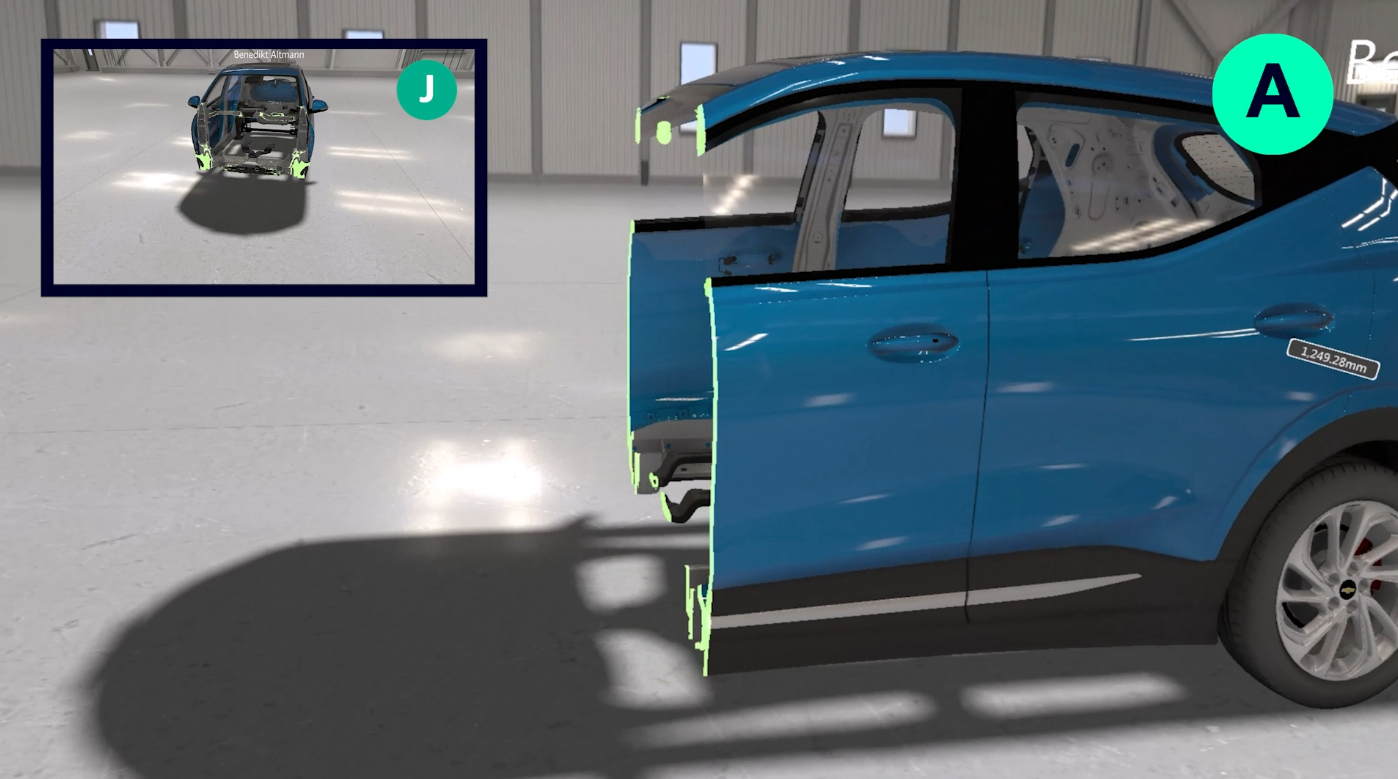

Immersive Engineering is pushing the boundaries of what’s potential in product design, heralding a brand new period in automotive collaboration. Engineers can open a car’s digital twin and step into an immersive workspace primarily based on prolonged actuality (XR) – the household of applied sciences that features digital, combined and augmented actuality. There is no such thing as a elaborate export or dataset duplication; each immersive surroundings runs on the identical Designcenter NX™ software program session.

The primary benefit is scale. At 1:1, a participant can stand beside the entrance meeting or lean in the direction of the wheel arch to grasp instantly what a service technician will face. Navigation is straightforward; the out-of-the-box Ring and Pointing controller are there to intuitively transfer by the house, level to things and choose elements. Moreover, appropriate controllers (assume a PS5 controller) can be used to navigate across the scene.

Subsequent, orientation. An built-in meeting view lets reviewers spotlight elements of the mannequin. The Part software cuts cleanly by the automotive, exposing inside elements beforehand unseen that means clearances, routing and potential interference dangers turn into seen to everybody.

When one thing wants nearer inspection, the Remodel software lets customers choose up, reposition and study elements in context. When a overview is required on an intricate, deeply embedded automotive half – for instance a gearbox, engine part or brake callipers – the power to isolate and carefully examine it’s invaluable. Doing so can present how a proposed repair might create a brand new downside elsewhere and eradicate points earlier than they come up.

A variety of instruments within the immersive surroundings assist preserve designs on observe. Using correct measurements imply reviewers can add dimensions to options, referencing precise factors and surfaces and monitoring modifications all the way down to the millimetre. Mark-up instruments enable customers to focus on areas that require consideration, then seize viewpoints as a typical reference that any participant can return to – whether or not they’re within the headset or becoming a member of from desktop. Feedback could be connected as easy notes towards particular areas, including additional context to design modifications.

All of the instruments a designer may wish are current inside Immersive Engineering. A digital monitor could be positioned, resized and positioned primarily based on the customers desire. On that monitor sits Designcenter NX, the place engineers could make modifications immediately within the native CAD surroundings with the mannequin nonetheless seen.

Some individuals will choose headsets for spatial judgement. Others might be part of with out one, utilizing a traditional display screen. Critically, wherever a stakeholder is predicated and no matter their function, they’ll entry the immersive surroundings in a method that works for them. It represents a impartial floor the place experience is shared and selections are recorded.

The ability of Immersive Collaborator

Siemens’ Immersive Collaborator stand outs for its potential to bridge geographical divides and produce groups, websites and areas collectively. By integrating reside updates and design modifications into conferences, it permits individuals to watch and work together with ongoing modifications. Its attain is really world; it may possibly join design leads in Europe and engineering groups in India and North America.

Immersive Collaborator helps a shared digital surroundings the place stakeholders achieve and act on insights by reviewing colleagues’ design selections and merging disparate workflows. This integration of Immersive Engineering accelerates design productiveness and fosters innovation, connecting individuals and departments to make prompt selections primarily based on a single supply of fact.

Partnerships driving a collaborative future

Siemens Immersive Engineering is an immersive surroundings designed for detailed engineering overview, linked to a core CAD dataset. A single shared design room for dispersed groups, suppliers and inside teams can meet in a collaborative surroundings, study merchandise at scale and seize design intent.

The advantages for automotive producers are wide-ranging. Automotive improvement can stumble on the handover factors: design to manufacturing, engineering to provider, idea to detailed packaging. Immersive Engineering reduces friction by making avoidable misunderstandings a factor of the previous. By slashing errors and resolution occasions, and bringing groups from throughout the globe collectively, it affords a blueprint for adapting to the subsequent era of automotive design. Early adopters are poised to steer the business into the long run and you may be one among them. Fill in your particulars now to be taught extra.